Anode Carrier

Counter Weight

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor for Rodded Anode Transfer

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor for Spent Anode Transfer

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

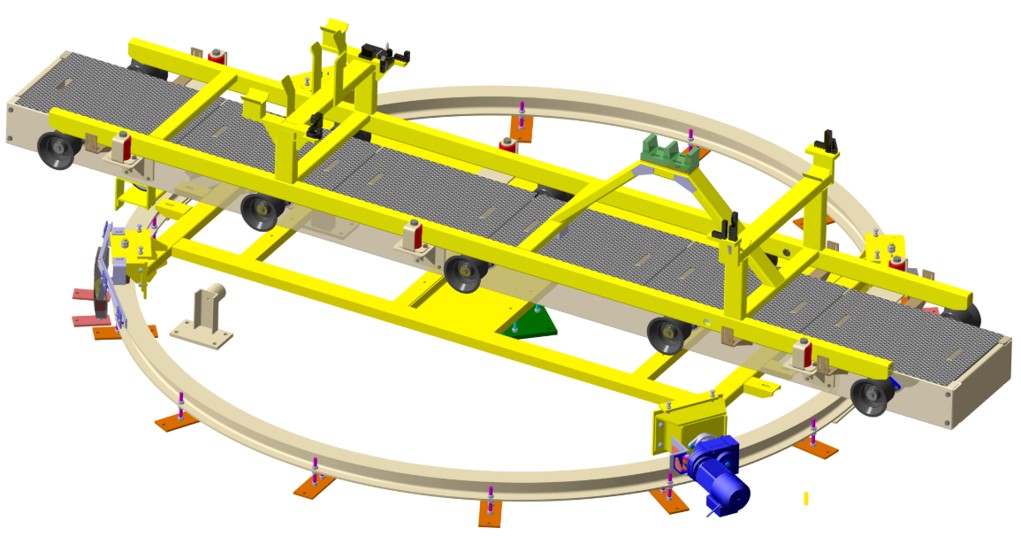

PnF system with Anode Carrier

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

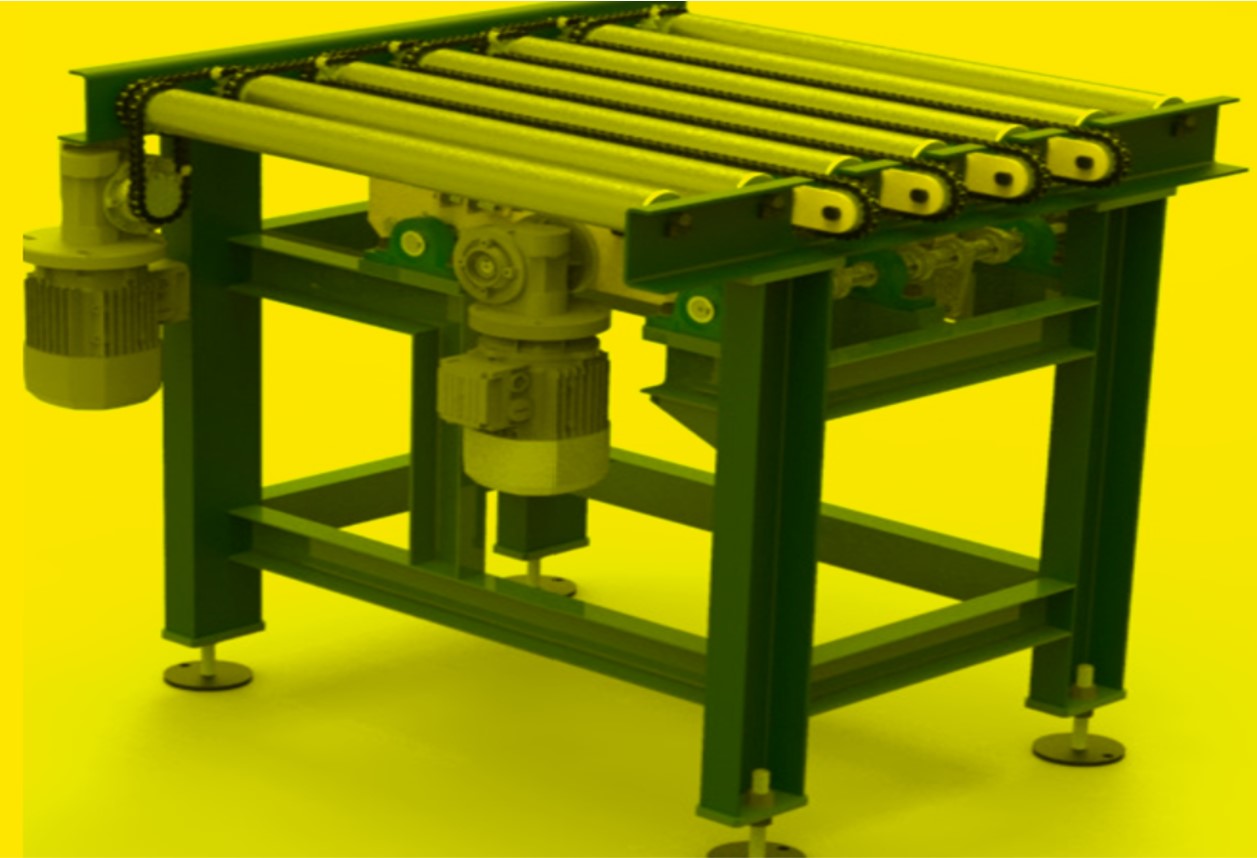

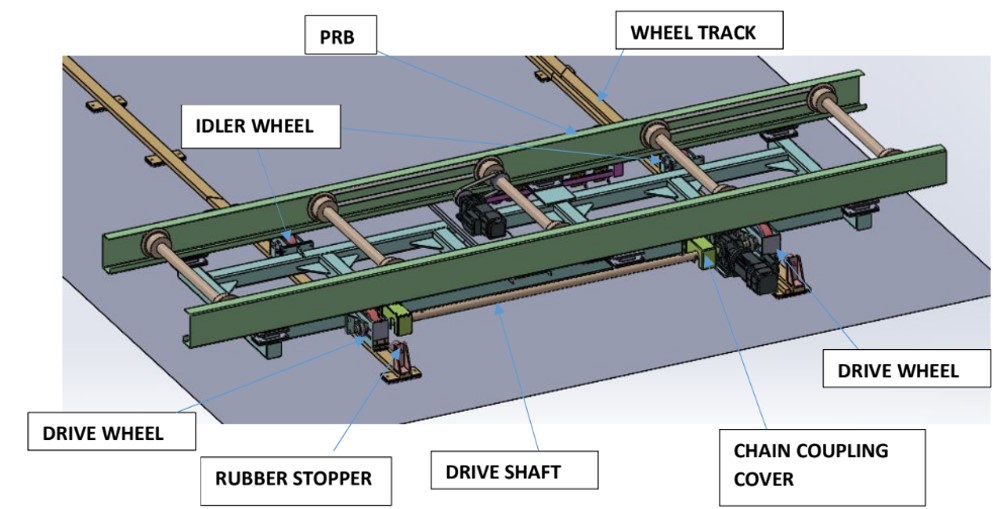

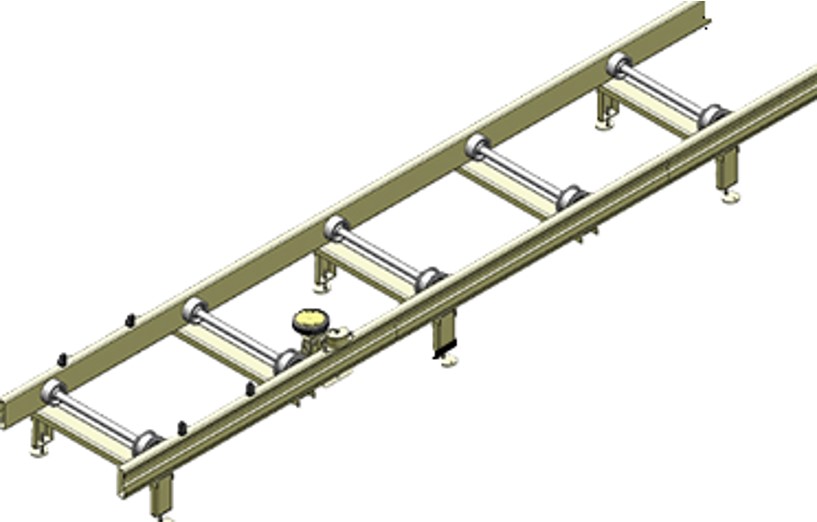

Roller Conveyor

Roller Conveyor

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Shot Blasting Machine

Shot Blasting Machine

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

EU9 Filter

Fine Filters

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

High Temp Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

High Temp Pre Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Pre Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

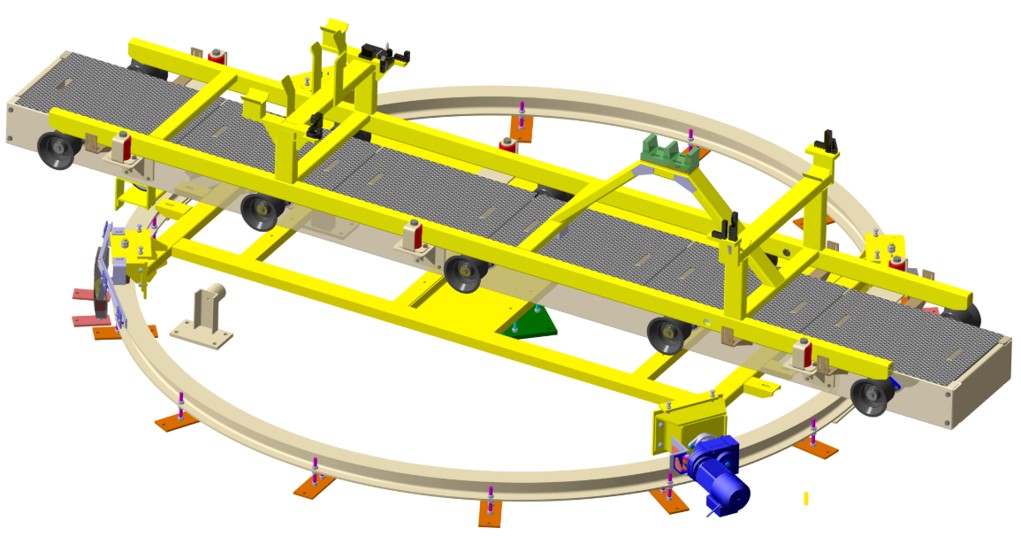

Turn Table

Transfer Car

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

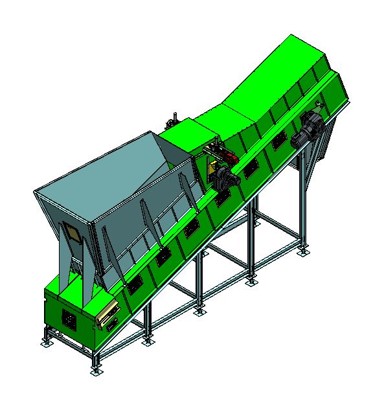

Slat Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Single Mast lift

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Rivetless Chain

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

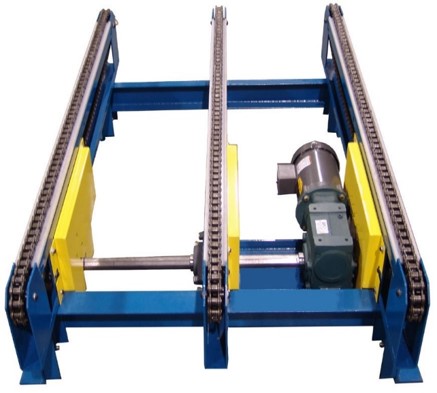

PNF Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Monorail Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

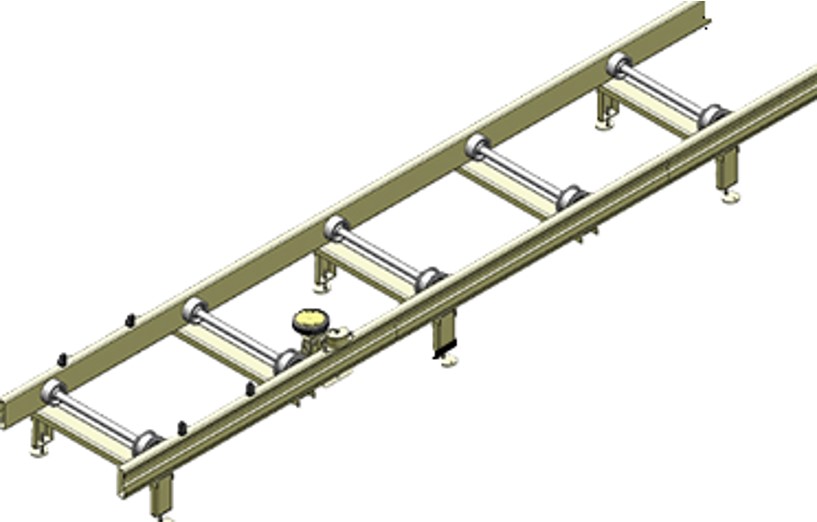

FRB

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

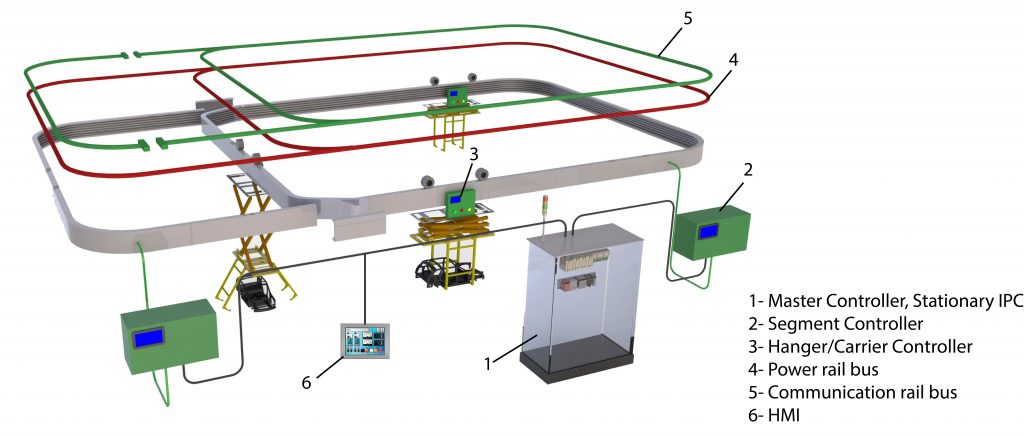

Automated Electrified Monorail System

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Automated Grab Crane

- for more than 500m3 volume storage handling

- Automated / Manual grab crane is best solution for higher storage management

- Flexibility for handling various moisture RDF, TDF, Biomass

- Flexibility for handling various grain size of RDF, TDF, Biomass

- Less power consumption, reduction on manual handling by front loader

- Reduction in truck movement in factory

- Less area requirement, for more volume as we can manage storage for upto 10m in height

- Disadvantage: dead stock of about 5 to 10%

LadderFEED

- Hydraulically operated ladders, pulls the AF on to next conveyor, periodically.

- Rugged design with negligible wear and tear capable for 200 m3/h OR 20tph.

- Requires chain belt conveyor for uniform material extraction.

- Direct truck loading on the ladder is feasible provides easy unloading. Full automated operation, with Red-Green signal and boom barrier for loading.

- Number of LadderFEED’s can be installed in a line and all can feed into single chain belt conveyor.

- Gain size got some limitation and it can handle up to 100mm grain size only.

ScrappFEED

(for more volume holding about 500m3)

- Strong bucket for scrapping the Alternate fuels and feeding to next chain conveyor.

- Rugged design with negligible wear and tear capable for 100 m3/h OR 10tph.

- Requires chain belt conveyor for uniform material extraction, as the scrapping is a cyclic activity of extraction.

- Direct truck tippler able to load on floor in the on the bunker. Fully automated operation, with Red-Green signal and boom barrier for loading.

- Number of ScrappFEED’s can be installed in a line and all can feed into single chain belt conveyor.

- Gain size got some limitation and it can handle up to 50mm grain size only.

HoppFEED

(for effective extraction)

- Synchronized with the dosing belt to control feeding as required

- Rugged design with high hopper capacity of up to 30 m3

- Accepts material from tippler truck, front loader, garb crane directly.

- Regulating drum and regulating foil is provided to ensure uniform output discharge

- Feeding capacity of up to 400 m3 /h

- Radar sensor, jamming sensor, position sensors, zero speed switch provides it necessary process control along with Siemens standards PLC system

WeighFEED

(for accurate dosing)

- Wide entry feed chute, allowing more wide HoppFEED to load into small wide WeighFEED

- Rugged design with high strength rollers & pulley capable for 400 m3/h

- Siemens system with weighing rollers & PLC for accurate control

- Complete automation with Siemens latest PLC system

- Integration with HoppFEED for controlled & uniform dosing

DosiFEED

(for compact extraction & dosing)

- Compact design with hopper & dosing arrangement

- Rugged design hopper capacity of 7 m3

- Regulating drum and regulating foil is provided to ensure uniform output discharge.

- Special weighing bridge designed for accurate weighing & dosing based on core siemens support

- Feeding capacity of up to 300 m3/h

- Complete automation with process sensors and PLC for efficient & safe control

Double DosiFEED

(for compact extraction & dosing into two lines)

- Compact design with hopper & dosing arrangement for two lines

- Rugged design hopper capacity of 15 m3

- Regulating drum and regulating foil is provided to ensure uniform output discharge in each line.

- Common hopper with uniform distribution by Radar sensor hopper level measurement.

- Feeding capacity of up to 300 m3/h in each line

- Complete automation with process sensors and PLC for efficient & safe control.

Magnetic Separator

- A magnetic separator is a device that uses magnetic fields to separate magnetic materials from non-magnetic ones in a mixture

Bulk Material Handling

Bulk Material Handling